EXPLORE OUR PRODUCTS

SZC® HANKOOK LUBE OIL is a manufacturing company based in South Korea

Specialising in industrial engineering lubricating oils such as Refrigeration oils, Air Compressor oils, Hydraulic oils, etc.

Established in 2000 we were soon set apart by our focus on R&D, quality and service. Since then, we have consistently made an effort to meet our customers’ needs and maintain our excellent reputation within a demanding and constant evolving industry

-

MINERAL OILS

-

PAO/AB FULL SYNTHETIC OILS

-

HYDROTREATED AMMONIA OILS

-

POE (POLYOLESTER) OILS

REFRIGERATION COMPRESSORS

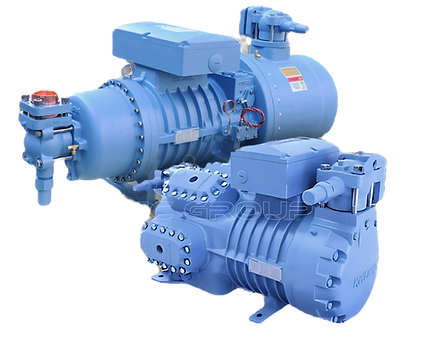

REFCOMP Founded in Lonigo, Italy in 1991, RefComp continues to provide superior semi-hermetic screw and piston compressors for industrial and commercial refrigeration, air conditioning, process cooling and heat pump markets.

In 2013, continuing its mission to provide solutions for the global air conditioning and refrigeration market, acquired the compressor technology and market of RefComp in Italy, and injected RefComp with new blood from the Swedish SRM patented technology.

In the collision and integration, RefComp has opened a new chapter in history with a more efficient and sustainable look, providing stable and technical support in key industries such as food, manufacturing, construction, pharmaceuticals, logistics.

-

Semi-Hermetic Piston Compressors

-

Semi-Hermetic Screw Compressors

-

CO2 Compressors

-

Wide Range and Applications

ICE MACHINES

SNOWKEY from Snowman Group is a global ice machine manufacturer specializing in various ice types, including flake, tube, and plate ice, for industrial and commercial applications like food processing, concrete cooling, and fishing. Key features include high efficiency, durability, adaptability to diverse environments (including harsh marine conditions), and the use of top-brand components for reliability. Snowkey offers customized solutions, full automation, and energy-saving designs to meet diverse customer needs and promote automated, hygienic ice production processes.

Snowkey Ice machine utilise REFCOMP Refrigeration piston or screw compressors

depending on the size and application of the ice machine

-

Types of ice machines we offer:

-

Flake Ice

-

Plate Ice

-

Ice Slurry

-

Tube Ice

-

Block Ice

-

REFRIGERATION PACKAGES

SNOWKEY from Snowman Group offer Refrigeration units and packages integrate both piston compressor and screw compressor technologies into a single system to provide flexible, energy-efficient, and reliable refrigeration. These modular units offer variable capacity control, advanced safety features, intelligent controls with remote monitoring, and are designed for simple maintenance and installation across various industrial applications.

Key Features

Hybrid Compressor Design:

Combines piston and screw compressors to optimize performance and efficiency for varied refrigeration loads.

Modular & Containerized:

Units are designed with a modular structure for simple maintenance and are available in containerized versions for easy relocation and stability against external conditions.

Energy Efficiency:

Incorporates multi-step and stepless capacity control, inverter control, and optimized component design to reduce operating costs.

Advanced Control Systems:

Features intelligent and automated control systems with remote monitoring capabilities for dynamic tracking and efficient operation.

Safety Features:

Equipped with comprehensive preventive safety systems, including protection modules, safety valves, password system for unauthorized access.

High-Quality Components:

Utilizes world-renowned brands for key electrical parts and durable, high-strength materials

like forged steel for rotors and high-strength ductile iron for housings.

Versatile Application:

Suitable for a wide range of industrial applications, including

pharmaceutical, chemical, food processing, fishing, dairy, etc

CONTAINERISED SYSTEMS

SNOWKEY from Snowman Group containerised systems are transportable, all-in-one industrial refrigeration units built inside standard ISO shipping containers. These systems are designed for rapid deployment in various industries and remote locations.

Key Features

Plug-and-play functionality: The systems are delivered pre-assembled and factory-tested. They only need to be connected to water and electricity on-site to begin operation, significantly reducing installation time.

Portability: Housed in durable 20 or 40-foot containers, the systems are easy to transport by truck, rail, or ship, making them ideal for temporary or remote projects.

Protected operation: The container provides a protective, weather-resistant shell that guards internal components against dust, moisture, and harsh external temperatures, ensuring stable operation even in extreme climates.

Space efficiency: The compact, integrated design eliminates the need for separate buildings or extensive on-site construction, saving space.

Diverse ice types: SNOWKEY offers systems that produce various types of ice, including flake ice, tube ice, plate ice, and block ice, depending on the application.

Automatic control: The systems feature an outstanding electric control system, often with components from brands like Siemens and Schneider. The system automatically manages ice production and storage, reducing labor needs.

Types of containerised systems

Containerised ice plants: These units produce and store large quantities of ice for various applications. They can include systems for flake ice, block ice, and tube ice.

Containerised automatic ice storage: These systems are used for storing large volumes of ice, with capacities ranging from 18 to 200 tons. They feature automated raking systems to manage ice storage.

Containerised concrete cooling systems: For large-scale construction projects like dams and bridges, these systems use ice to cool concrete. They can include containerised ice-making and water-chilling units.

Containerised water chillers: These units are designed to provide

chilled water for industrial processes.

AMMONIA SCREW PACKAGES

SrmtEC by Snowman Group 1 and 2-stage ammonia screw compressor packages feature their patented "i" type rotor profile for high efficiency and durability, high-strength ductile iron housing, wear-resistant roller bearings, and integrated oil channels. Packages are available in open-type and semi-hermetic designs, offering stepless capacity control and adaptability for low and medium-high temperature refrigeration in industrial applications like dairies and breweries

Key Features and Components

Patented Rotor Profile: SRMTEC uses a patented "i" type rotor profile with a 5+7 lobe ratio, optimized for high efficiency, stability, and durability.

Advanced Bearings: Precision, wear-resistant roller bearings are designed for long operating life, with some designs specifying up to 80,000 or 100,000 hours.

Integrated Oil System: Oil channels are integrated into the compressor design for secure and effective lubrication of all critical components.

Shaft Seal (Open-Type): An innovative shaft seal structure with a silicon carbide wear surface ensures high sealing efficiency, stability, and durability.

Vi Control: The internal compression ratio (Vi) can be optimized and controlled (manually or automatically) to ensure high-efficiency operation under various working conditions and load demands.

Economizer System: The two-stage packages can include an economizer to absorb heat from high-pressure liquid, increasing system efficiency (COP).

Package Types

Open-Type Packages: Known for their robust and reliable design, featuring horizontal oil separation.

Semi-Hermetic Packages: Offer a compact structure, easy maintenance, and zero refrigerant leakage due to the absence of a shaft seal.

MOBILE AMMONIA SYSTEMS

SrmtEC from Snowman Group Mobile Refrigeration Station gathers the major refrigeration equipment, e.g. compressor, condenser, liquid receiver, gas- liquid separator and electronic control components, into a standard container. Cooling tower or evaporative condenser is put on the top of the container. The container serves as the engine room of the refrigeration system. Professional design, reasonable layout, less space and flexible installation. High cooling efficiency, solid performance, controlled capacity for low temp and super low temp working conditions. As many as eight compressors can be parallel operated. Intelligent control, simple operation, smooth and safe running, applicable for medium and small logistic cold storage or large cold room that needs the expanded cold storage.

Key Features

-

World- leading SRM NH3 semi-hermetic screw compressor.

-

Plate and shell heat exchanger and direct expansion system forms the refrigeration system that requires minimal NH3 charge.

-

Container as the bearer saves the work of the machine room design

-

Easy moving, quick-site installation period, and reduced cost.

-

NH3can be reduced as much as 50- 80%, thus reducing the potential risk.

-

Three-in-one vessel (gas-liquid separator), which also functions as

heat exchanger and improves the cooling efficiency. -

PLC automatic control and robust failure warning warranty.

-

High efficiency oil separator, its efficiency as high as 99.9%.

-

The valves and accessories are from the world famous manufacturers,

providing guaranteedprecision and reliability. -

Factory assembled, central control, and guaranteed quality.

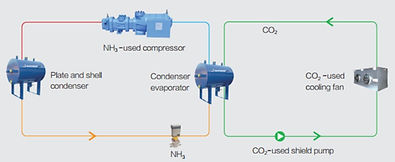

CO2/AMMONIA SECONDARY UNITS

SrmtEC from Snowman Group high performance and environment-friendly NATURE Series NH3/CO2 Secondary Units to meet the application requirements of high temp refrigeration, low- temp refrigeration and quick freezing. NH3/CO2 units take CO2 as the secondary refrigerant and NH3 as the primary, forming the composite refrigeration system. This combination not only ensures environmental safe guarding but also solves the issue of high- charging amount of NH3 in the traditional systems, which is a safety hazard. The series includes the design of the automatic control, excellent energy efficiency, high integration, and reliable safety.

Key Features

-

NATURE CO2 Secondary

-

World- leading SRM NH3 semi-hermetic screw compressor.

-

High- speed variable frequency permanent magnet synchronous motor saves more energy than the routine motors.

-

Highly integrated plate and shell type heat exchanger:heat exchange and separation are one, high heattransfer efficiency, compact structure, fully closed structure.

-

High- pressure resistant, guaranteed safety.

-

Preventive safety warning system makes automatic operation possible and reduces the number of on- site management personnel.

-

Module design reduces the design cost of the machine room refrigeration; integral and distributive installation are available.

-

Minimal NH3 charge.

-

CO2 makes the system fully clean, free of refrigerant oil residue, heat transfer is much more efficient than the traditional systems of NH3 or freon, cooling is rapid and there is no issue of cleaning the refrigeration oil residue at the refrigeration end.

-

The valves and sensors are all from the global- known brand, high efficiency and reliable safety.